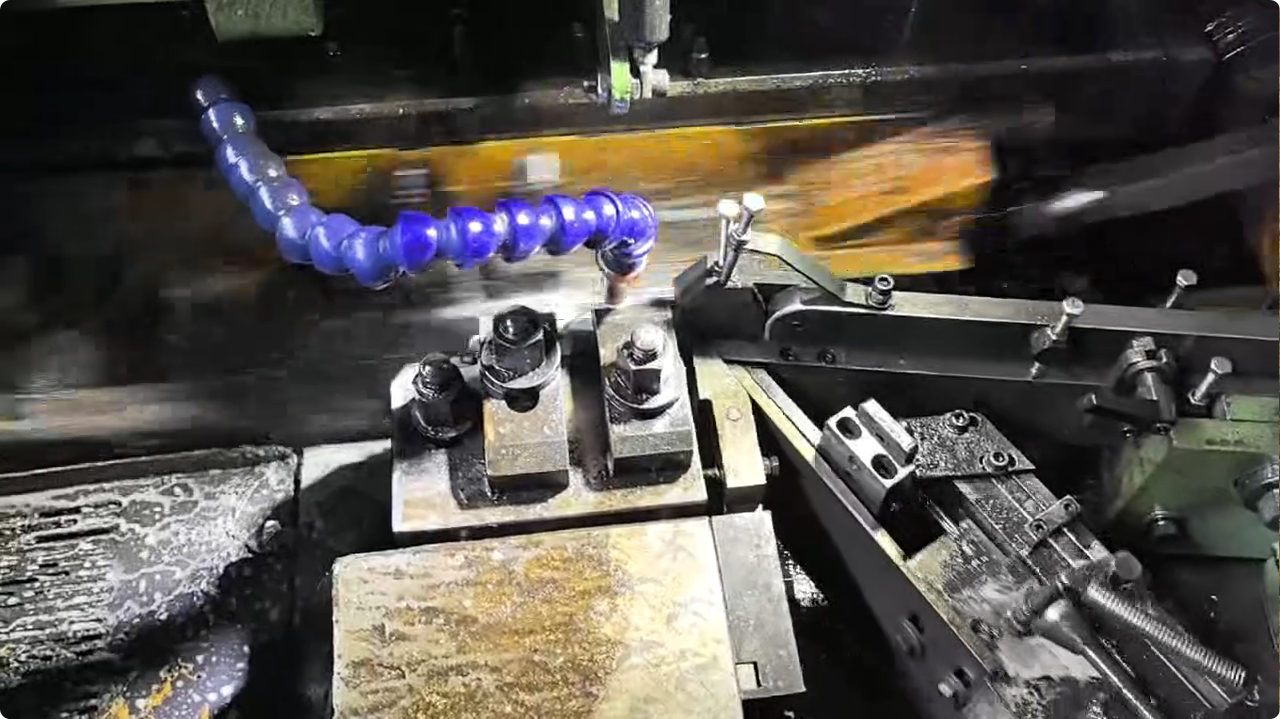

Two-Die Heading Machine is a cold forming device equipped with two dies, mainly used to produce standard fasteners such as bolts, pins, and rivets. It performs two successive heading operations—typically for performing and final shaping—to ensure accurate geometry and improved structural integrity. The working principle involves cutting wire to a fixed length, then using two heading stages to form the desired shape gradually. This machine is widely used in fastener manufacturing where efficiency, consistency, and durability are essential.

| Model | YTB-25152 |

| Blank Diameter(mm) | 8 |

| Blank Length Max(mm) | 152 |

| Stroke(mm) | 210 |

| Blanks Per Min | 60-70 |

| Die Dia(mm) | 55 |

| Cof-off Die Dia(mm) | 28 |

| Punch Die(1st)(mm) | 42 |

| Punch Die(2st)(mm) | 42 |

| Body Motor | 7 1/2HP |

| Oil Pump motor | 1/4HP |

| Overall Dimenslon L*W*H(mm) | 4000*1600*1650 |

| Weight Approx(kg) | 5500 |

When choosing equipment for fastener manufacturing, understanding the differences between two-die heading machines and other heading technologies is essential. Here's how two-die heading machines compare with common alternatives:

Two-die machines are a subset of cold heading technology optimized for intermediate complexity parts, offering good throughput with precise control. Other cold heading machines with more dies can handle more complex parts but at increased cost and complexity.