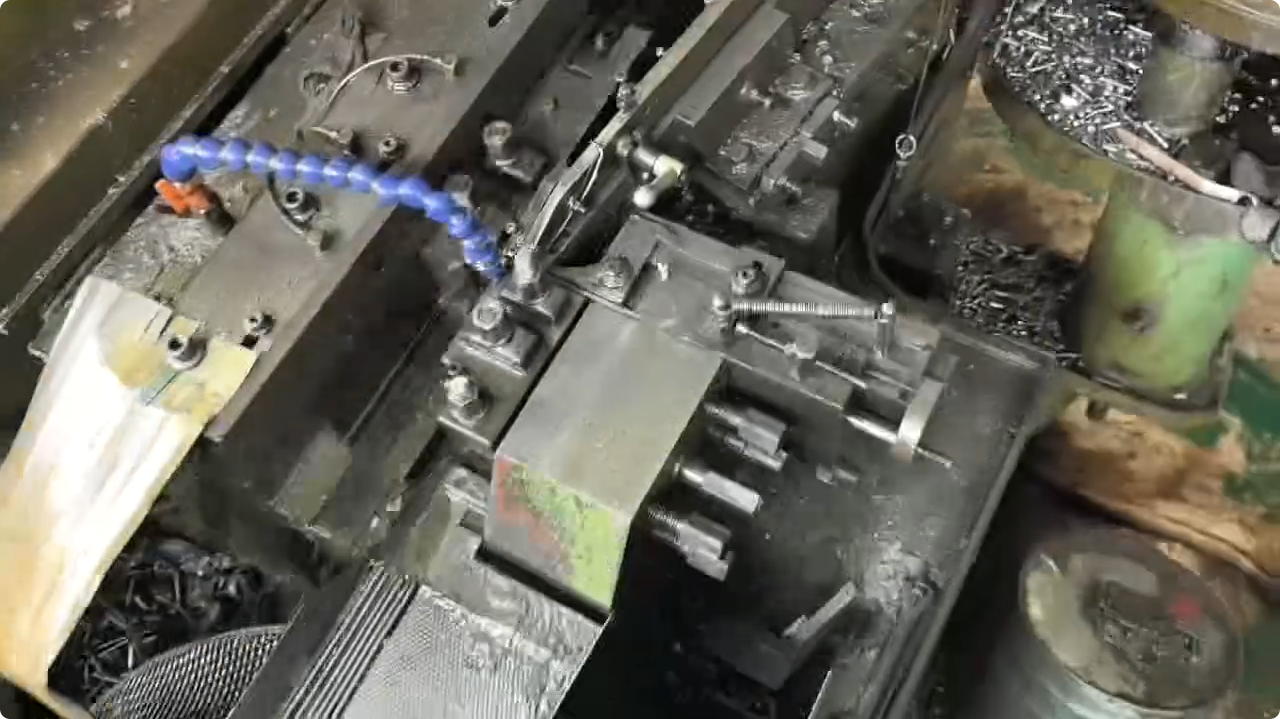

High Speed Cold Heading Machine is a cold forming machine with two working stations, mainly used to produce standard fasteners such as bolts, rivets, and pins. This equipment can efficiently process simple parts with stable quality and high output. The working principle of the two-die cold heading machine is to use a high-speed ram to press the metal blank into the desired shape in two forming steps, ensuring accurate dimensions and consistent performance.

| Model | YT-0524 |

| Blank Diameter (mm) | 0.6 - 3.5 |

| Blank Length Max (mm) | 24 |

| Stroke (mm) | 38 |

| Blanks Per Min | 170 - 260 |

| Die Dia (mm) | 20 |

| Cut-off Die Dia (mm) | 13.5 |

| Punch Die (1st) (mm) | 18 |

| Punch Die (2nd) (mm) | 18 |

| Body Motor | 1 HP |

| Oil Pump Motor | 1/4 HP |

| Overall Dimension L × W × H (mm) | 1250 × 800 × 930 |

| Weight Approx (kg) | 800 |

High speed cold heading machines are vital for producing fasteners used in industries like automotive, aerospace, electronics, and construction. A core factor that ensures their success is precision engineering. Achieving micron-level accuracy allows these machines to produce fasteners with consistent quality, strength, and dimensional accuracy.

Cold heading forms metal parts by shaping wire or rod without melting. Since this process happens at high speeds, even tiny errors in precision can cause defects such as dimensional inconsistencies, surface cracks, or weak points. Precision engineering is therefore essential to maintain strict tolerances and ensure product quality.

Machines designed with precision components help reduce rejects, minimize material waste, and improve production yield. For manufacturers, this means cost savings and reliable output that meets customer expectations.

Several critical aspects make high speed cold heading machines precise:

Advanced Die Design: The die shapes the fastener and must be made from durable materials like tool steel or carbide. Precision dies reduce wear and maintain accurate shaping over time.

Accurate Control Systems: Computerized controls regulate stroke length, feed rate, and pressure. They adjust in real time to keep the forming process stable despite material or wear variations.

Robust Mechanical Parts: High-quality shafts, bearings, and linkages minimize vibrations and mechanical errors at high speed, ensuring stable operation.

Implementing precision engineering in cold heading machines offers multiple advantages:

In aerospace and automotive sectors, where safety and durability are critical, precision cold heading machines produce bolts, pins, and rivets that meet strict standards. Electronics manufacturing requires tiny, highly accurate fasteners for assembling delicate devices, further emphasizing the need for precise machines.

Digitalization is shaping the future of precision in cold heading. IoT sensors allow predictive maintenance, reducing unexpected breakdowns. AI-driven controls can optimize machine parameters automatically, adapting to different materials and designs for better precision and efficiency.

Precision engineering is the foundation of effective high speed cold heading machines. Combining advanced dies, accurate controls, and solid mechanical design helps manufacturers produce high-quality fasteners efficiently. As demands grow for tougher, more complex parts, investing in precision technology is key to maintaining competitiveness and meeting industry standards.