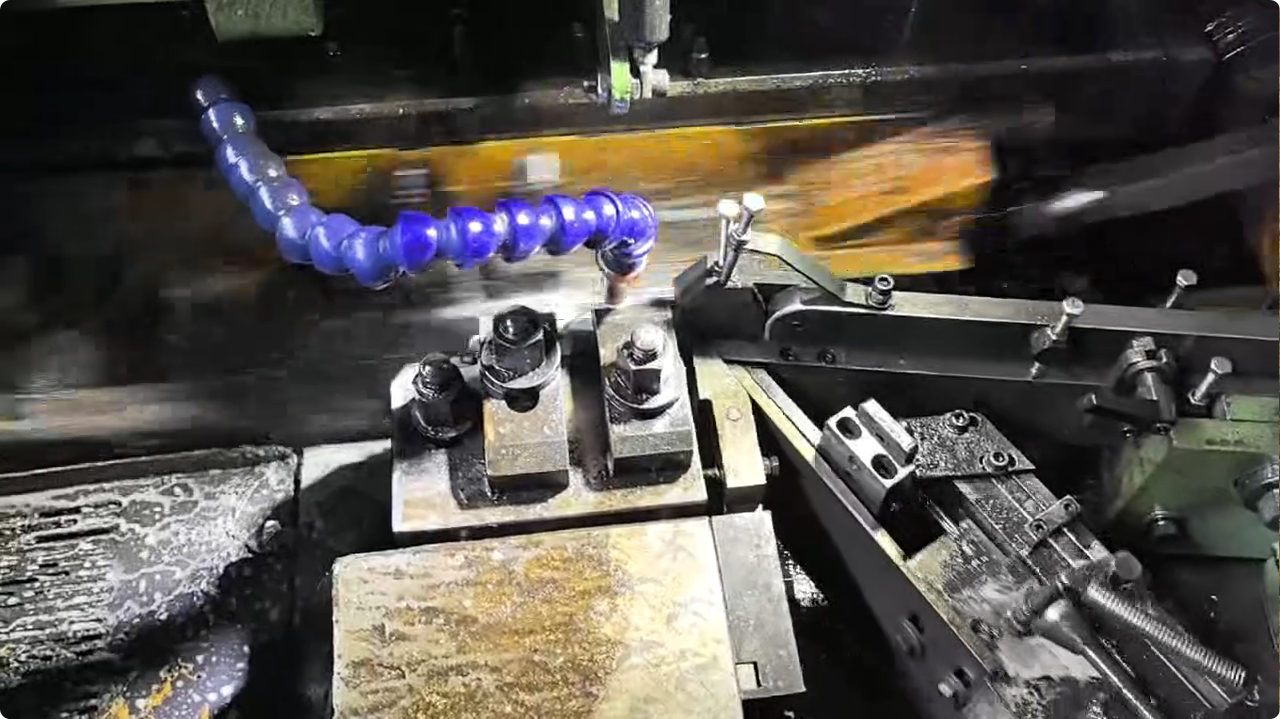

2-Station Cold Heading Machine is a cold forming device with two working positions, mainly used to produce basic fasteners such as bolts, rivets, and pins. It performs two successive forming actions to shape metal blanks, ensuring consistent size and structural integrity. This machine is suitable for high-speed production lines where simplicity, efficiency, and output stability are key requirements.

| Model | YT-1032 |

| Blank Diameter(mm) | 2-4 |

| Blank Length Max(mm) | 32 |

| Stroke(mm) | 60 |

| Blanks Per Min | 160-180 |

| Die Dia(mm) | 30 |

| Cof-off Die Dia(mm) | 15 |

| Punch Die(1st)(mm) | 24 |

| Punch Die(2st)(mm) | 20 |

| Body Motor | 2HP |

| Oil Pump motor | 1/4HP |

| Overall Dimenslon L*W*H(mm) | 1620*900*1000 |

| Weight Approx(kg) | 1200 |

In the fast-paced world of metal forming, choosing the right cold heading machine can dramatically impact your production efficiency and product quality. The 2-station cold heading machine strikes a perfect balance between speed, versatility, and cost-effectiveness, making it a popular choice for many manufacturers. If you’re considering upgrading or purchasing a new machine, understanding why a 2-station model could be your best fit is crucial.

A 2-station cold heading machine features two sequential working stations within one machine frame, allowing two forming operations to occur in a single cycle. This configuration increases production speed without the complexity or cost of multi-station machines.

By performing two forming steps per cycle, these machines effectively double the production speed compared to single-station machines. This boost means more parts produced per hour and faster fulfillment of orders.

Compared to more complex multi-station machines, 2-station models typically come with a lower purchase price and easier maintenance requirements. This makes them ideal for small to medium-sized operations looking for high performance without the high capital expense.

Many 2-station cold headers can be adapted for various part shapes and sizes, making them suitable for a range of fasteners and formed components. Custom tooling allows manufacturers to switch between product lines with relative ease.

Their smaller size compared to multi-station machines saves valuable factory floor space, allowing integration into existing production lines without major rearrangements.

Manufacturers with moderate production volumes aiming to scale up efficiently. Companies producing a variety of fastener types and sizes. Operations seeking a balance between capital expenditure and productivity gains. Factories with limited space but high demand for quality formed parts.

Regular preventive maintenance is vital to keep the 2-station cold header running smoothly. Key practices include routine lubrication of moving parts, periodic inspection of tooling and dies, monitoring and adjusting machine settings to maintain precision, and training operators in troubleshooting common issues.

The 2-station cold heading machine offers an excellent blend of speed, flexibility, and affordability. For many manufacturers, it represents the sweet spot between single-station simplicity and multi-station complexity. By choosing the right 2-station machine tailored to your production needs, you can improve efficiency, reduce costs, and maintain high product quality—all essential for staying competitive in today’s manufacturing landscape.