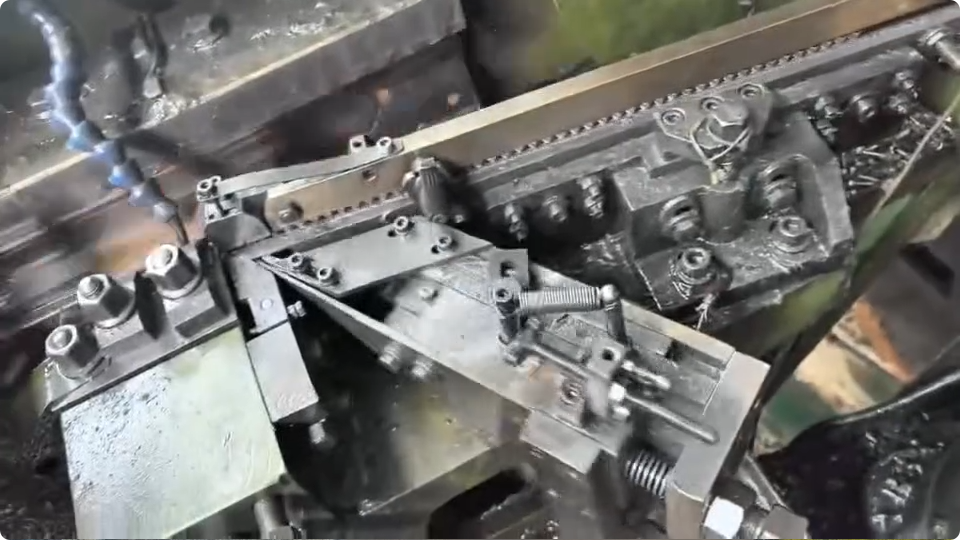

This High Speed Cold Header is a cold heading machine with two working stations, mainly used to produce simple fasteners such as bolts, rivets, and pins. This equipment performs two-stage forming in a high-speed cycle, enabling efficient and continuous production. The working principle of the two-station cold header is to shape metal blanks into the required form through successive punching actions, offering stable quality and increased productivity for standard fastener manufacturing.

| Model | YTB-0524 |

| Blank Diameter(mm) | 0.6-3.5 |

| Blank Length Max(mm) | 24 |

| Stroke(mm) | 38 |

| Blanks Per Min | 170-260 |

| Die Dia(mm) | 20 |

| Cof-off Die Dia(mm) | 13.5 |

| Punch Die(1st)(mm) | 18 |

| Punch Die(2st)(mm) | 18 |

| Body Motor | 1HP |

| Oil Pump motor | 1/4HP |

| Overall Dimenslon L*W*H(mm) | 1250*800*930 |

| Weight Approx(kg) | 850 |

First, a quick refresher: a high speed cold header machine forms metal parts—like bolts, screws, and fasteners—at remarkable speeds by shaping metal wire or rod cold, without heating. This cold forming process results in high precision, excellent material utilization, and superior mechanical properties compared to machining or hot forging.

When evaluating the cost of high speed cold header machines, consider these key components:

The sticker price varies widely based on machine capacity, automation level, and customization. Basic models might start in the lower range, while fully automated multi-station headers with advanced controls can command a premium.

Tooling is essential and often a significant recurring cost. Dies wear out or need adjustment, especially with high-volume production or tougher materials.

Running costs include:

Regular maintenance extends machine life and performance. Unplanned downtime can be costly, impacting production schedules and customer commitments.

ROI is your compass for evaluating whether the cold header machine is worth the investment. It’s usually expressed as a percentage and factors in all costs versus gains over a defined period.

ROI (%) = (Net Profit from Investment / Total Investment Cost) × 100

To get an accurate picture, consider these variables:

Investing in a high speed cold header machine is a strategic move that can transform your manufacturing efficiency, reduce costs, and improve product quality. While the upfront cost can seem significant, careful cost analysis and realistic ROI calculations often reveal compelling financial benefits. By understanding all cost components and how they tie into production benefits, you can confidently select a machine that fits your operational needs and financial goals.