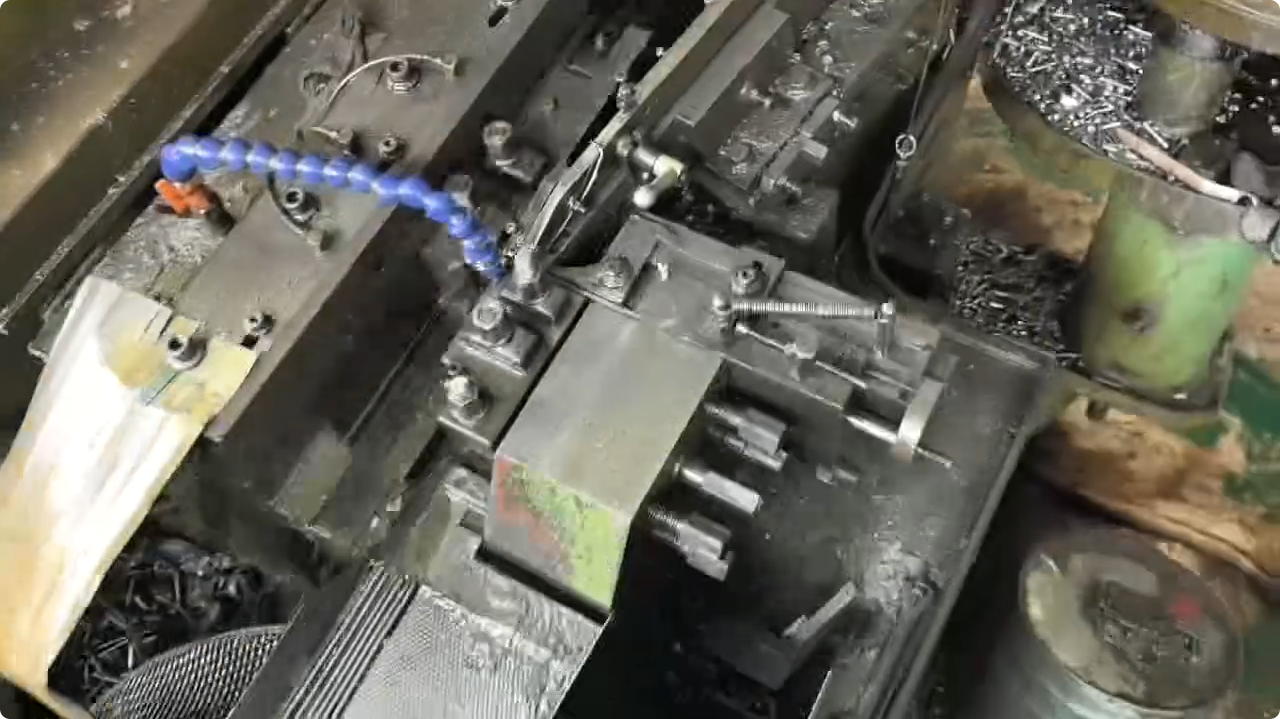

Thread Rolling Dies are specialized forming tools used in thread rolling machines to create external threads on fasteners such as bolts, screws, and studs. Made from high-strength alloy steel and precision-ground for accuracy, these dies plastically deform the fastener surface under pressure to form clean, consistent threads without material removal. This cold forming process enhances thread strength, surface finish, and fatigue resistance. Thread rolling dies are essential for high-speed, high-volume production in industries such as automotive, construction, and general hardware manufacturing.

| Model | YTB-04/40 |

| Blank Diameter(mm) | 2-4 |

| Thread Length(mm) | 35 |

| Moving Dies Stationary Length(mm) | 65*75*20 |

| Main Motor(HP) | 2HP-1/8HP |

| Capacity PCS/MIN | 200-280 |

| Overall Dimenslon L*W*H(mm) | 1600*1100*1400 |

| Weight Approx(kg) | 1300 |

Thread rolling dies are essential tools in fastener manufacturing, but improper handling can cause accidents or damage. Following safety guidelines ensures smooth operation and protects both workers and equipment.

Always use safety glasses, gloves, and protective clothing to prevent injuries from flying debris or accidental contact with moving parts.

Keep all machine guards in place before starting operations.

Never bypass safety interlocks or remove protective covers.

Inspect dies for cracks, wear, or misalignment.

Damaged dies can break during operation, posing serious safety risks.

Only trained personnel should install or replace dies.

Make sure dies are securely mounted and aligned according to manufacturer specifications.

Keep the area around the machine free of scrap material, oil spills, and tools to prevent slips or interference with moving parts.

Loose items can get caught in the machine, causing injuries or equipment damage.

Follow the manufacturer’s schedule for maintenance to prevent die or machine failure.

Proper lubrication reduces friction and overheating, lowering the risk of accidents.

Ensure operators know the location and operation of emergency stop buttons.

Keep first aid kits accessible and train staff on basic emergency response.