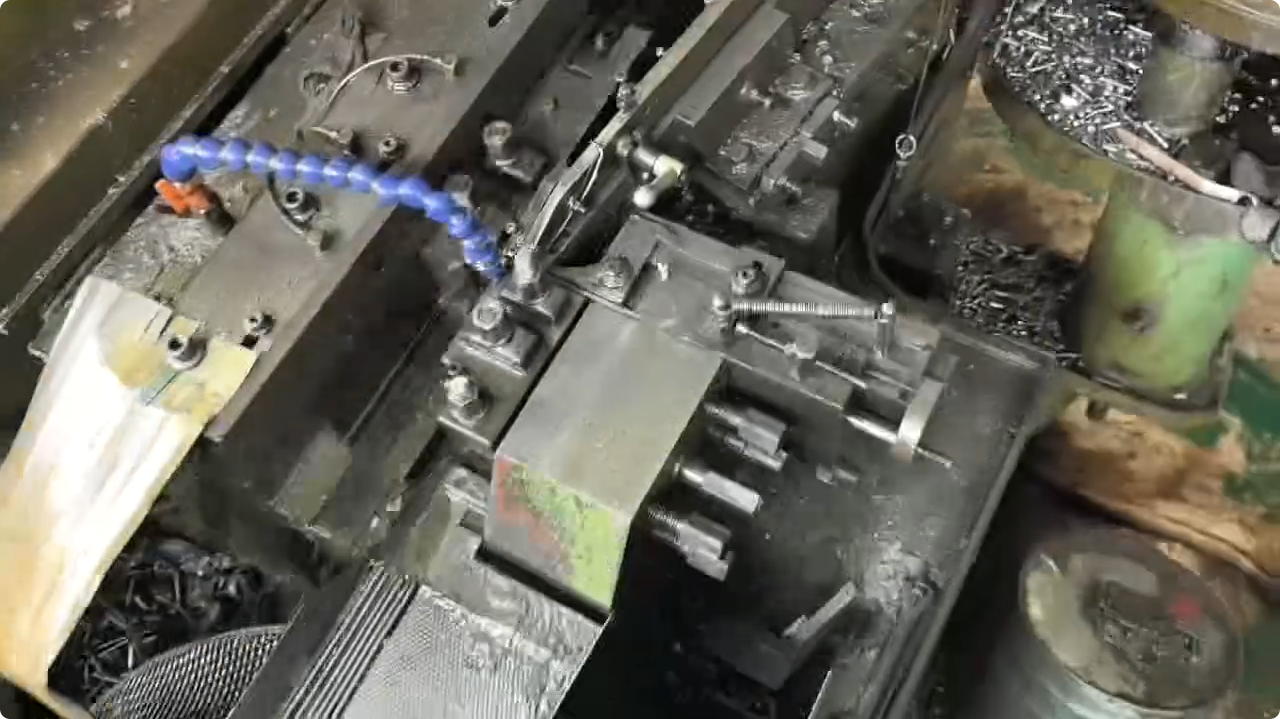

Thread Roller is a specialized tool used in thread rolling machines to create external threads on fasteners such as bolts, screws, and studs. It works by plastically deforming the material surface through cold rolling, producing durable and precise threads without cutting. Thread rollers are made from high-strength materials and are precision-ground to ensure consistent thread quality. They are essential components in high-speed manufacturing lines within automotive, construction, and industrial sectors.

| Model | YTB-10 |

| Blank Diameter(mm) | 6-10 |

| Thread Length(mm) | 65 |

| Moving Dies Stationary Length(mm) | 150*165*25 |

| Main Motor(HP) | 20HP |

| Capacity PCS/MIN | 130-140 |

| Overall Dimenslon L*W*H(mm) | 3100*1700*2000 |

| Weight Approx(kg) | 4750 |

Modular thread rollers are designed with interchangeable components, allowing quick adjustments to accommodate different thread sizes, materials, and production specifications. This adaptability ensures that manufacturers can respond rapidly to new product requirements without extensive downtime or costly machine replacements.

As businesses expand or diversify their product lines, production volume needs can change dramatically. Modular thread rollers enable scalable manufacturing by allowing additional modules or upgraded components to be integrated seamlessly. This flexibility supports both small-batch customization and large-scale mass production, ensuring efficiency regardless of order size.

Even with modular configurations, these thread rollers maintain consistent thread accuracy and strength. Automated controls and precise alignment of modules minimize errors and reduce waste. Manufacturers benefit from reliable, high-quality output across a wide variety of products, reducing the risk of rework and enhancing overall productivity.

With the rise of advanced alloys, lightweight materials, and smart factory integration, manufacturers need equipment that can evolve alongside their operations. Modular thread rollers are designed for compatibility with new materials, automation systems, and digital monitoring tools. Investing in this technology ensures production lines remain flexible, efficient, and competitive for years to come.

Modular Thread Rollers combine adaptability, precision, and scalability to support future-proof manufacturing. By enabling flexible production, reducing downtime, and maintaining consistent quality, they provide manufacturers with a strategic advantage in an ever-changing industrial environment. For companies seeking long-term value and operational resilience, modular thread rollers are a practical and forward-thinking choice.