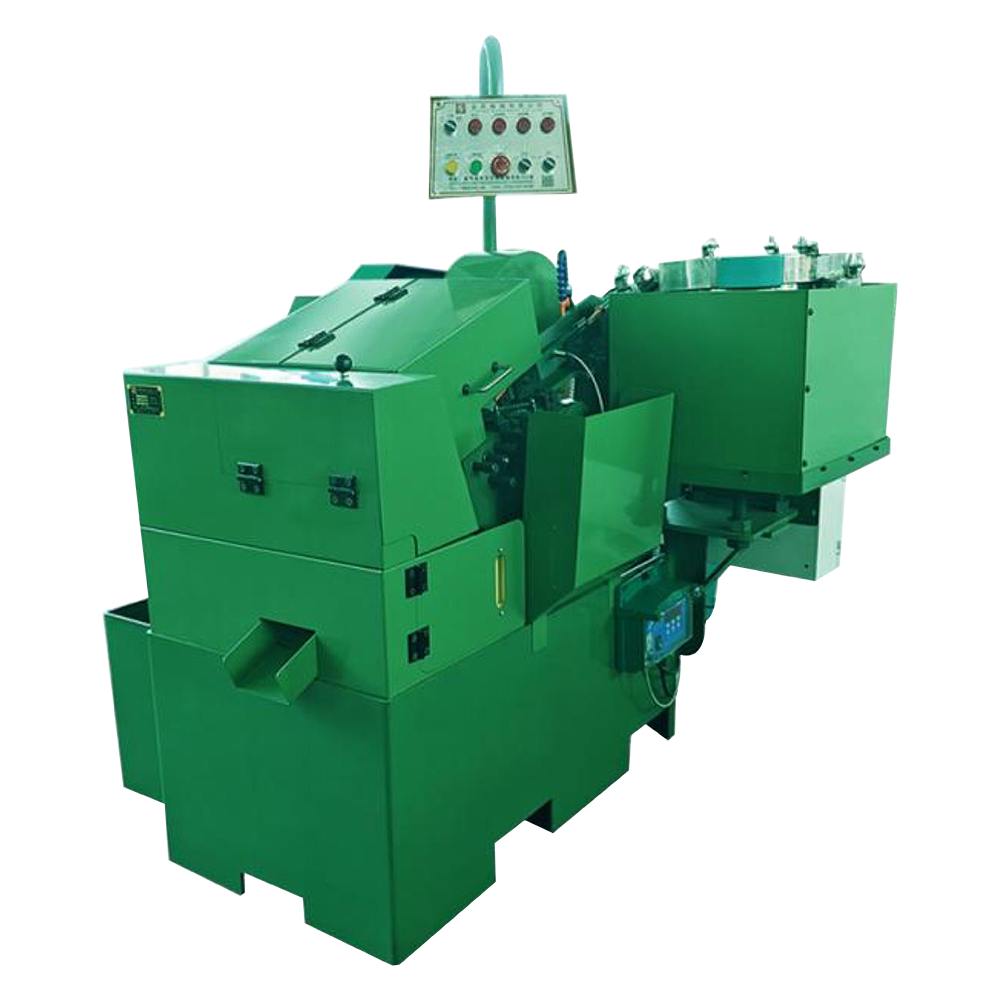

The High Efficiency Thread Rolling Machine is designed for rapid and accurate threading of fasteners such as bolts, screws, and studs. Utilizing advanced rolling technology, it forms external threads through plastic deformation without cutting, ensuring strong and smooth threads. Equipped with automated feeding and rolling systems, this machine significantly increases production speed while maintaining consistent thread quality. It is widely used in automotive, electronics, and general manufacturing industries where high throughput and precision are essential.

| Model | YT-3/16/65 Z |

| Blank Diameter(mm) | 2-5 |

| Thread Length(mm) | 60 |

| Moving Dies Stationary Length(mm) | 90*75*25 |

| Main Motor(HP) | 3HP-1/8HP |

| Capacity PCS/MIN | 220-260 |

| Overall Dimenslon L*W*H(mm) | 1600*1200*1700 |

| Weight Approx(kg) | 1250 |

High efficiency thread rolling machines can create threads in a fraction of the time compared to conventional threading methods. Since the process involves cold forming rather than cutting, multiple threads can be shaped in one rapid pass. This results in significantly higher output, making it ideal for large-scale industrial production where speed is critical.

Unlike conventional threading, which removes material, thread rolling compresses and displaces the metal. This cold forming process strengthens the grain structure of the material, producing threads with higher tensile strength and better fatigue resistance. The result is a finished product that lasts longer under mechanical stress.

Thread rolling naturally generates smoother surfaces compared to cutting tools. The absence of sharp tool marks reduces friction and wear during use, which not only enhances the visual quality but also improves the performance of the threaded part in its final application.

Conventional threading methods cut away material, often resulting in chips and wasted metal. Thread rolling, on the other hand, reshapes the material without removing it. This near-zero waste process leads to cost savings on raw materials and makes production more environmentally friendly.

Because thread rolling tools are designed for forming rather than cutting, they tend to last significantly longer. Reduced wear and tear mean fewer replacements, less downtime, and lower maintenance costs. For manufacturers, this directly translates into higher efficiency and reduced operational expenses.

High efficiency thread rolling machines provide superior precision and repeatability. Once set up, they produce uniform threads with minimal variation, ensuring consistent quality across large production runs. This is particularly valuable in industries where tight tolerances are essential.