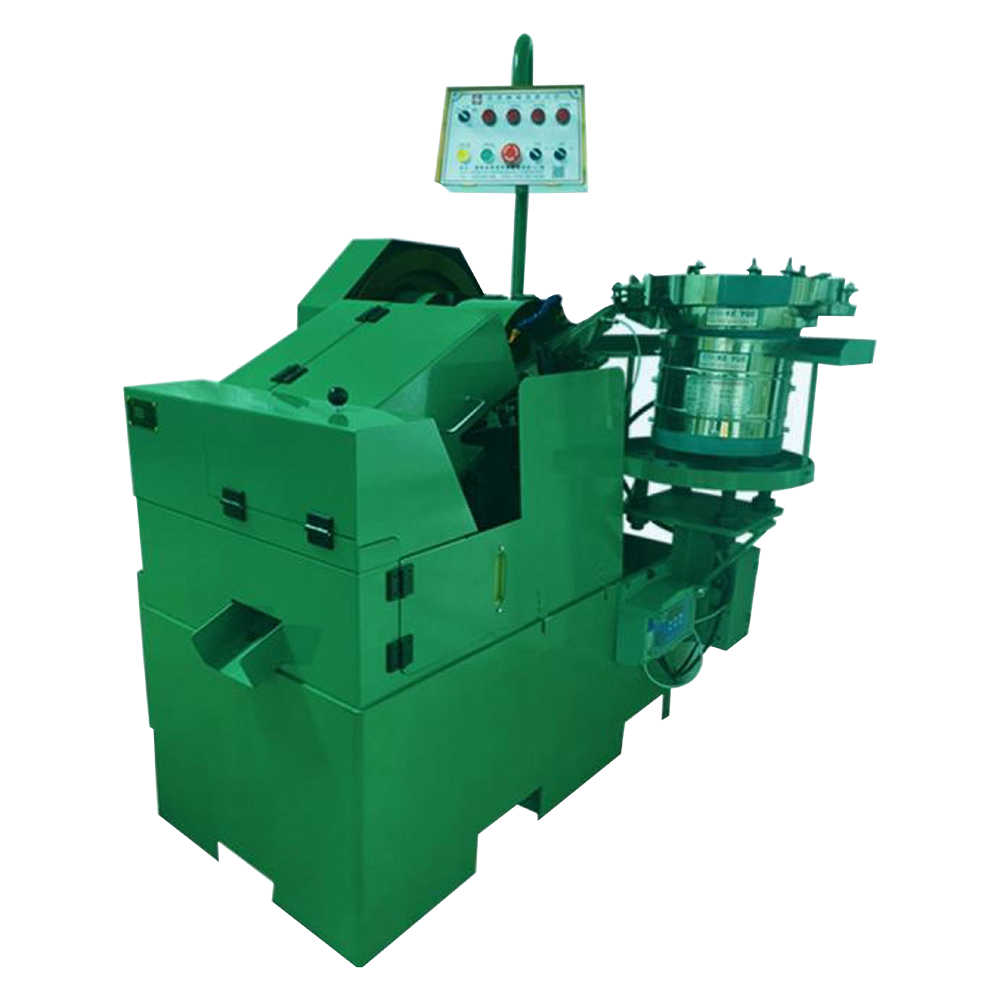

This Heavy-duty Thread Rolling Machine is designed for forming threads on large-diameter or high-tensile fasteners such as bolts, studs, and rods. It uses hardened dies and high-pressure rolling to plastically deform the material surface, creating strong and accurate threads without cutting. This process enhances fatigue resistance and surface finish. With its robust frame and powerful drive system, the machine is ideal for heavy industries like construction, automotive, energy, and rail, where thread strength and reliability are essential.

| Model | YT-04/40 |

| Blank Diameter(mm) | 2-4 |

| Thread Length(mm) | 35 |

| Moving Dies Stationary Length(mm) | 65*75*20 |

| Main Motor(HP) | 2HP-1/8HP |

| Capacity PCS/MIN | 200-280 |

| Overall Dimenslon L*W*H(mm) | 1600*1100*1800 |

| Weight Approx(kg) | 1050 |

A Heavy-duty Thread Rolling Machine is defined by its ability to handle high-strength materials, large workpieces, and high production demands.

Key characteristics include:

Can process tough materials such as high-strength steel, alloy steel, and stainless steel.

Capable of handling workpieces with tensile strength above 800 MPa, which standard machines may struggle with.

Suitable for bolts, screws, or pins with larger diameters or longer lengths.

Designed with stronger frames and tooling rigidity compared to light-duty machines.

Can run under heavy loads for long periods, ideal for high-volume manufacturing.

Built to maintain performance during extended shifts.

Provides greater pressure and torque to form threads accurately in high-strength materials.

Core components such as machine frame, slides, and rolling dies are made from heavy-duty materials to ensure long-term stability and low maintenance.

Can handle complex threads, fine threads, or non-standard profiles, sometimes forming multiple thread sections in one operation.