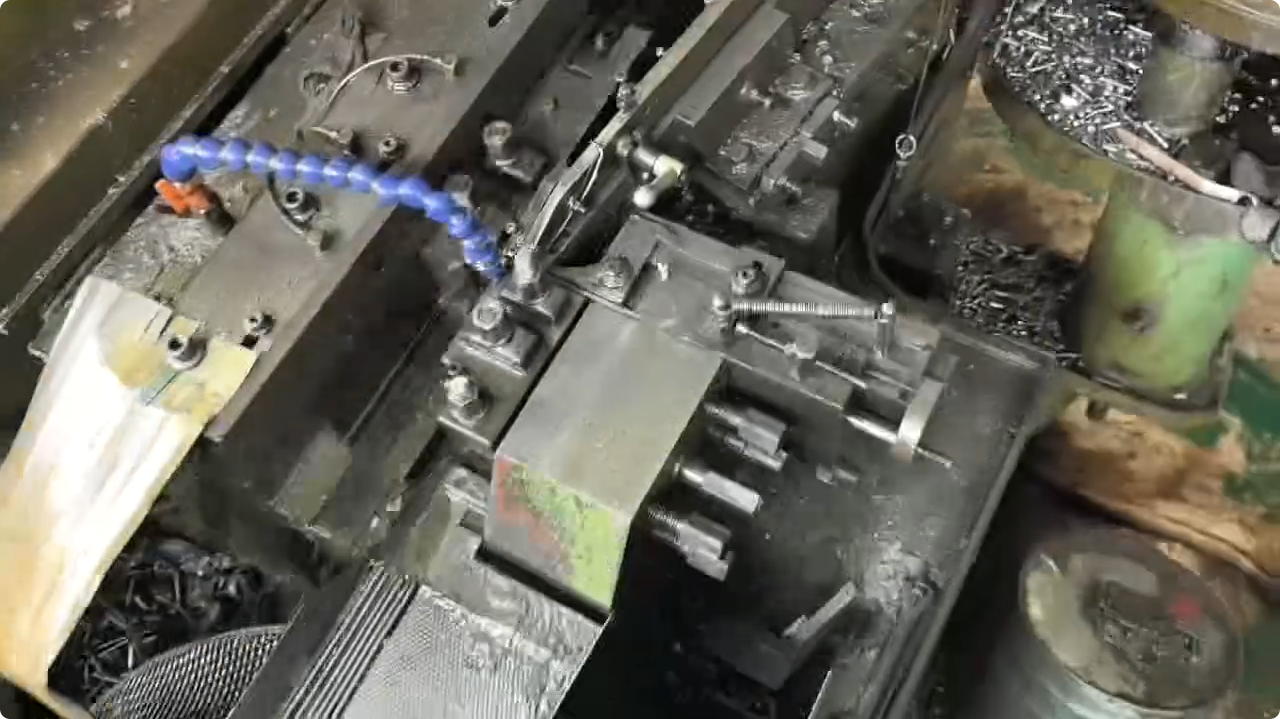

Automobile Parts Forming Machine is a cold forming device mainly used to manufacture automotive components such as bolts, shafts, pins, and specialty fasteners. Designed for high-volume production, it ensures dimensional accuracy and material strength critical to automotive applications. The machine operates by feeding and forming metal blanks through controlled high-speed punching or pressing, shaping each part with precision and consistency. It is widely used in the automotive industry for its ability to produce complex parts efficiently and reliably.

| Model | YTB-2076 |

| Blank Diameter(mm) | 6 |

| Blank Length Max(mm) | 76 |

| Stroke(mm) | 120 |

| Blanks Per Min | 80-100 |

| Die Dia(mm) | 45 |

| Cof-off Die Dia(mm) | 25 |

| Punch Die(1st)(mm) | 36 |

| Punch Die(2st)(mm) | 36 |

| Body Motor | 5HP |

| Oil Pump motor | 1/4HP |

| Overall Dimenslon L*W*H(mm) | 2700*1100*1250 |

| Weight Approx(kg) | 2600 |

In the competitive automotive manufacturing industry, minimizing waste during parts forming not only reduces costs but also supports sustainable production goals. Here are some effective strategies to reduce waste in automotive parts forming machines:

Using advanced software for material nesting and precise blank sizing ensures maximum use of raw materials, reducing scrap rates. Choosing forming processes like cold heading or precision stamping can also minimize excess material removal.

Well-designed and maintained dies and molds reduce defects such as burrs, folds, or cracks that lead to rejected parts. Using modular and quick-change tooling can decrease downtime and prevent waste during mold changes.

Real-time monitoring of machine parameters (pressure, speed, temperature) helps detect deviations early, preventing defective batches. Integration with IoT sensors allows for predictive maintenance and process optimization.

Consistent material quality reduces forming failures. Partnering with reliable steel or alloy suppliers and performing incoming inspections prevents waste caused by substandard materials.

Skilled operators can adjust settings proactively to maintain part quality. Regular maintenance reduces unexpected breakdowns and the scrap generated during restarts.

Implementing scrap collection systems and recycling processes helps recover metal for reuse, reducing overall material costs and environmental impact.

By applying these strategies, manufacturers can significantly reduce waste, improve efficiency, and contribute to greener automotive production.