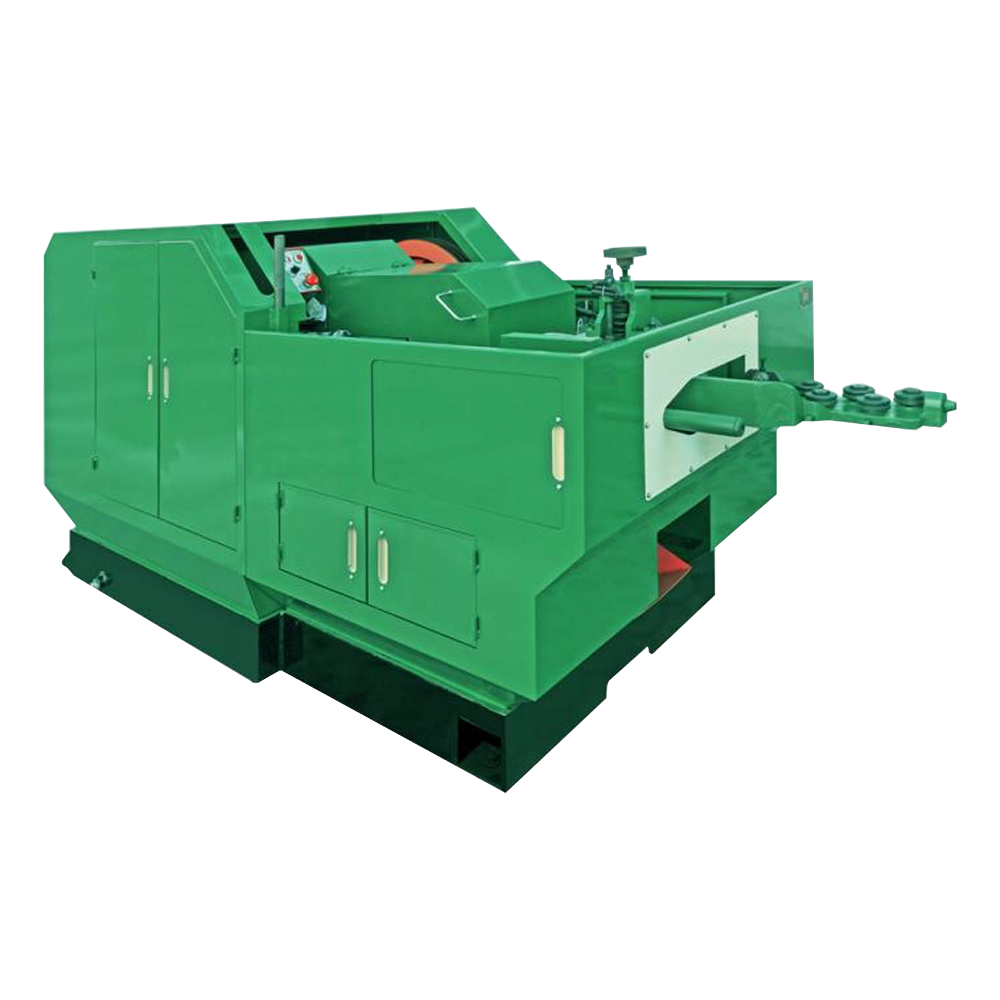

2-Die Bolt Making Machine is a cold heading machine with two forming stations, specially designed for producing standard bolt blanks. It performs two-stage forming—typically upsetting and heading—to accurately shape metal wire into bolt heads. This machine is widely used in fastener manufacturing for its high efficiency, stable performance, and ability to maintain consistent product dimensions. The working principle involves feeding metal wire, cutting it to length, and then forming it through two dies in quick succession, ensuring reliable and repeatable output.

| Model | YT-2076 |

| Blank Diameter(mm) | 6 |

| Blank Length Max(mm) | 76 |

| Stroke(mm) | 120 |

| Blanks Per Min | 80-100 |

| Die Dia(mm) | 45 |

| Cof-off Die Dia(mm) | 25 |

| Punch Die(1st)(mm) | 36 |

| Punch Die(2st)(mm) | 36 |

| Body Motor | 5HP |

| Oil Pump motor | 1/4HP |

| Overall Dimenslon L*W*H(mm) | 2700*1100*1250 |

| Weight Approx(kg) | 2600 |

A 2-Die Bolt Making Machine is a specialized cold forming machine used to produce bolts efficiently and with high precision. The “2-die” design means the machine uses two forming dies and one punch to shape the bolt in two main stages: first forming the bolt head’s basic shape, and then refining it to its final dimensions.

This process takes place at room temperature, without heating the material, which preserves the metal’s grain structure and improves its strength. It also minimizes waste, as the machine forms near-net shapes directly from wire rod.

2-Die bolt makers are widely used in industries such as automotive, construction, and machinery manufacturing. They are ideal for producing standard and high-strength bolts in large volumes. Modern machines often integrate automatic wire feeding, cutting, and quality inspection, allowing for high production speeds—often hundreds of bolts per minute—while maintaining consistent quality.

Compact, efficient, and reliable, the 2-Die Bolt Making Machine remains one of the most cost-effective solutions for large-scale bolt production.