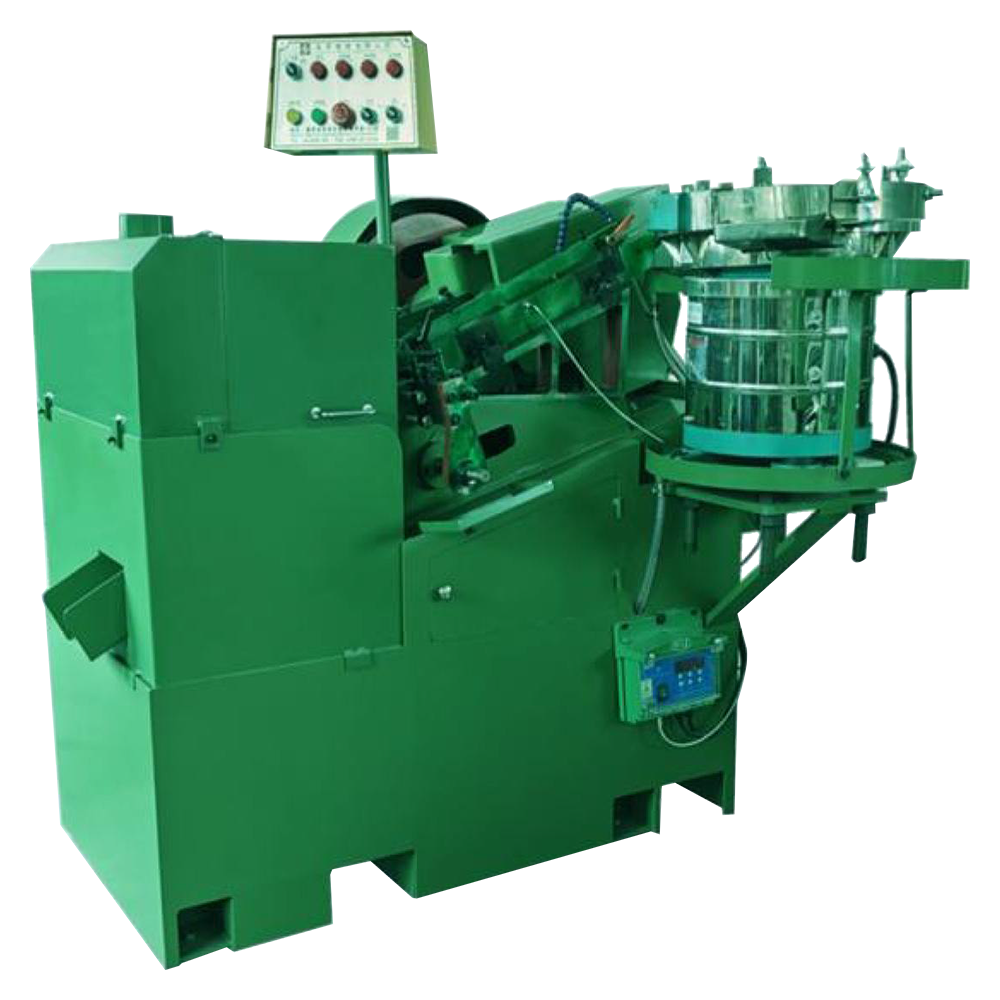

Precision Thread and Form Rolling Machine is specialized equipment designed to create high-accuracy threads and complex forms on fasteners such as screws, bolts, and custom parts. It uses cold rolling technology to plastically deform the surface, ensuring superior thread quality and dimensional consistency without cutting. This machine is equipped with precise control systems to handle intricate shapes and tight tolerances, making it ideal for demanding industries like aerospace, automotive, and electronics where reliability and precision are critical.

| Model | YT-06/57 Z |

| Blank Diameter(mm) | 3-6 |

| Thread Length(mm) | 50 |

| Moving Dies Stationary Length(mm) | 90*105*25 |

| Main Motor(HP) | 5HP-1/8HP |

| Capacity PCS/MIN | 170-200 |

| Overall Dimenslon L*W*H(mm) | 1900*1500*1600 |

| Weight Approx(kg) | 1800 |

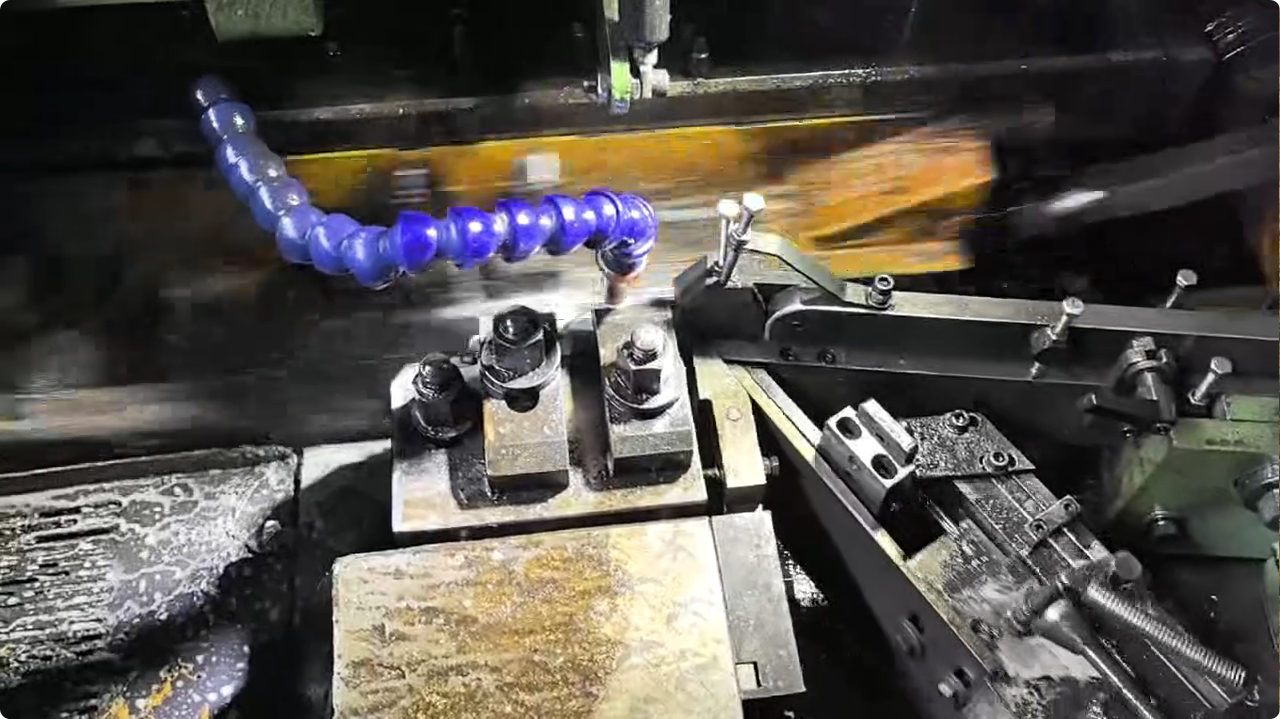

Unlike conventional cutting methods, thread rolling is a cold forming process. Instead of removing material, it reshapes and compacts the metal’s structure, preserving its natural grain flow. This process results in a much smoother surface with no burrs or sharp edges. In many cases, the finish is already suitable for use straight from the machine, eliminating the need for polishing or grinding.

Precision thread rolling machines are engineered to deliver uniform results across every piece. The pitch, flank angle, and overall geometry of the threads remain consistent throughout the production run. Because the threads come out so precise, manufacturers no longer need to spend additional time correcting dimensional errors or sorting out defective parts. This reliability directly translates into fewer secondary operations.

Rolled threads do more than just look clean; they are also mechanically superior. The rolling process induces surface-level work hardening, which increases the thread’s fatigue resistance and load-bearing capacity. At the same time, it avoids the micro-cracks and stress risers often caused by cutting. By removing these weak points, the need for post-process strengthening or repairs is greatly reduced.

Fewer post-processing steps mean lower costs in labor, energy consumption, and equipment wear. Production lines become leaner, cycle times shorten, and manufacturers can achieve faster delivery schedules. For industries where precision and efficiency are equally critical—such as aerospace, automotive, and medical device manufacturing—these savings are particularly valuable.

These small steps help preserve the benefits of precision rolling and ensure that post-processing is kept to a minimum.

Precision thread rolling is more than a manufacturing method—it is a pathway to efficiency. Producing threads that are strong, smooth, and dimensionally precise from the start reduces or even eliminates the need for costly post-processing. For manufacturers looking to save time, reduce waste, and deliver consistent quality, it is an approach well worth considering.