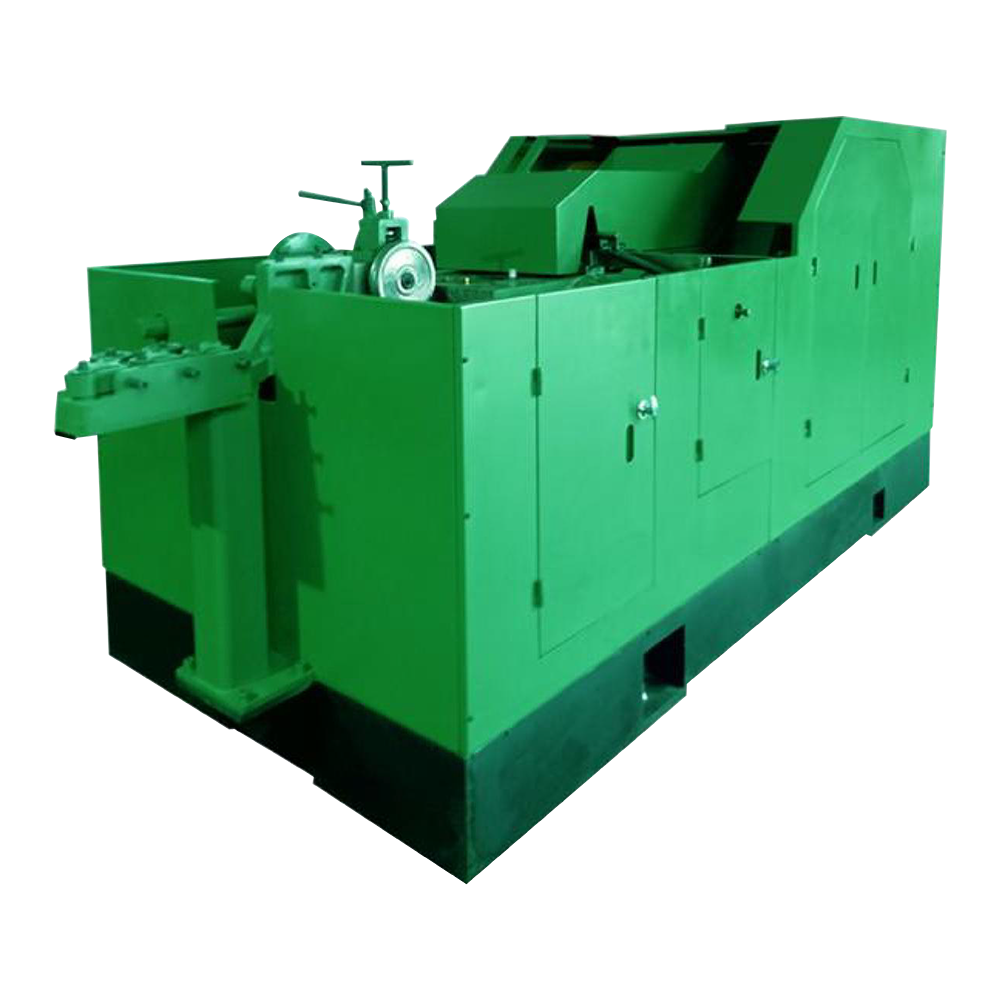

This 2-Station Cold Header is a cold heading machine with two working positions, mainly used to produce basic fasteners such as bolts, rivets, and pins. It performs two sequential forming steps to shape metal blanks efficiently, ensuring uniform dimensions and consistent quality. The machine operates by cutting the wire to length and then forming it through two punches in rapid succession. With its high-speed cycle and reliable output, the 2-station cold header is well-suited for standard fastener production in general manufacturing industries.

| Model | YT-25152 |

| Blank Diameter(mm) | 8 |

| Blank Length Max(mm) | 152 |

| Stroke(mm) | 210 |

| Blanks Per Min | 60-70 |

| Die Dia(mm) | 55 |

| Cof-off Die Dia(mm) | 28 |

| Punch Die(1st)(mm) | 42 |

| Punch Die(2st)(mm) | 42 |

| Body Motor | 7 1/2HP |

| Oil Pump motor | 1/4HP |

| Overall Dimenslon L*W*H(mm) | 4000*1600*1650 |

| Weight Approx(kg) | 5500 |

The machine should accommodate a wide variety of bolt diameters and lengths, allowing manufacturers to produce different fastener types without frequent equipment changes.

Look for machines capable of high strokes per minute, ensuring efficient mass production while maintaining consistent quality.

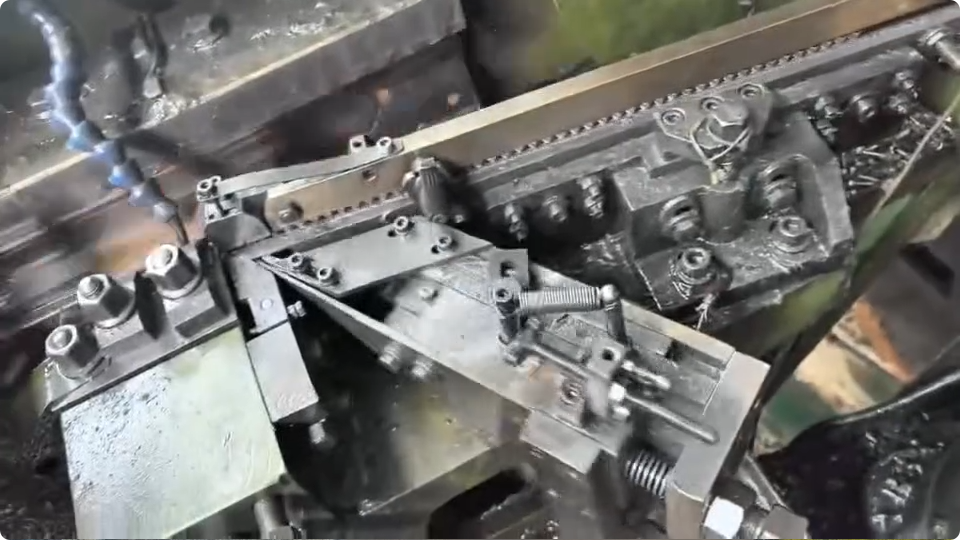

Fast and easy die changes help minimize downtime during product switches, improving overall manufacturing flexibility and reducing setup times.

Ensure the cold header can handle multiple materials such as carbon steel, stainless steel, aluminum, and brass to meet diverse application needs.

Automatic wire feeding, cutting, and part ejection systems reduce manual labor, increase throughput, and maintain stable production flow.

Servo-driven systems offer lower energy consumption compared to traditional drives, while designs focused on ease of maintenance help reduce machine downtime and operating costs.