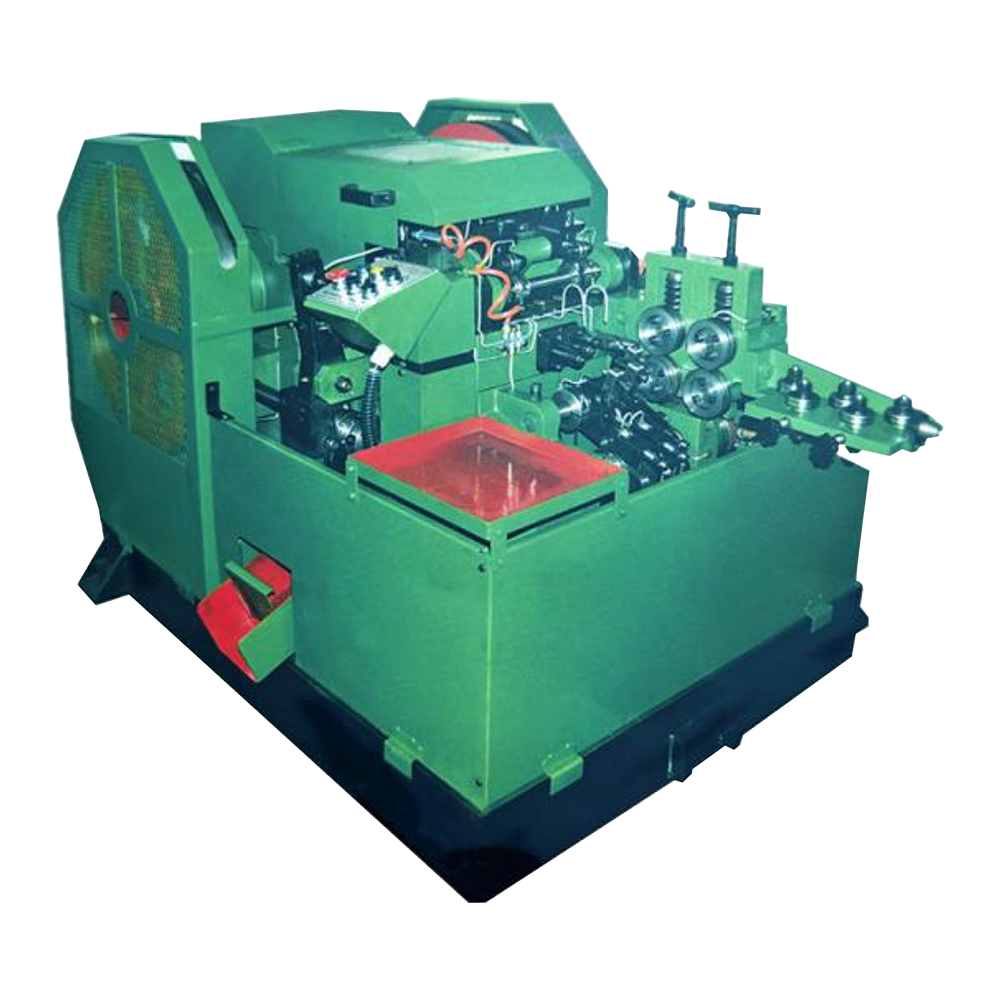

2 Die 4 Punch Cold Header is a precision cold forming machine with two dies and four punches, mainly used to manufacture complex fasteners such as high-strength bolts, screws, and custom-shaped parts. It enables multiple forming actions in a single production cycle, allowing for intricate part geometry and tight dimensional control. The working principle involves progressive deformation of metal blanks through sequential punches, providing excellent forming accuracy and surface finish. This machine is ideal for automotive, aerospace, and industrial fastener applications requiring high performance and efficiency.

| Model | YT-1524 |

| Blank Diameter(mm) | 5 |

| Blank Length Max(mm) | 35 |

| Main Die Dia(mm) | 46*85 |

| Punch Die Dia(mm) | 31*70 |

| Cut-off Die Dia(mm) | 19 |

| Main Motor Power(HP) | 3 |

| Pump Power(HP) | 1 |

| Capacity(PCS/MIN) | 60-100 |

| Pressure Force(Ton) | 15 |

| Overall Dimenslon L*W*H(mm) | 1900*1290*1150 |

| Weight Approx(kg) | 2200 |

With four punches spread across two dies, the machine can perform multiple forming steps in one cycle.

Ideal for fasteners requiring intricate head designs, multiple diameters, or secondary features without extra machining.

Multiple punches allow gradual shaping, reducing material stress and improving dimensional consistency.

Produces parts with tight tolerances, critical for automotive and aerospace applications.

Certain operations like piercing, trimming, or pre-threading can be integrated into the heading cycle.

Saves time, reduces labor, and lowers production costs compared to simpler machines.

More forming stages mean smoother material deformation, lowering the risk of cracks or surface defects.

Particularly beneficial for high-strength or exotic alloys.

Eliminates the need to transfer parts between machines for extra forming, speeding up total production time.

Can handle standard bolts, custom screws, specialty rivets, and precision pins in one machine, reducing the need for multiple equipment types.