Modern manufacturing demands high-efficiency, high-precision processes, particularly in fastener production. Cold heading has emerged as a preferred method for producing bolts, screws, and other metal components with minimal waste and consistent quality.

This guide explores the cold heading process, the equipment involved, its advantages, suitable materials, common applications, and practical tips for maintaining quality and extending tool life.

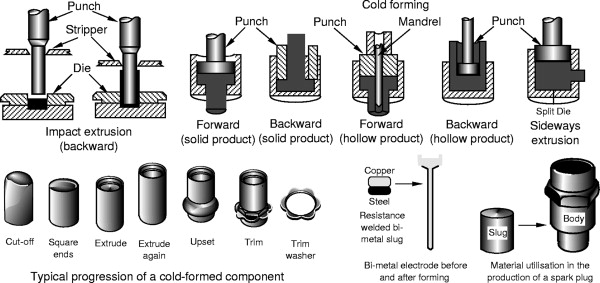

Cold heading is a metal forming process performed at room temperature, where raw material is shaped into a finished part using high pressure. The process begins with feeding metal wire or rods into the machine. A series of dies and punches then applies precise force to form the desired shape. Unlike cutting or machining, material is displaced rather than removed, preserving strength and improving surface finish. This efficient method allows for rapid production of components with consistent dimensions, making it ideal for high-volume manufacturing.

The primary components of a cold heading machine include the dies, punches, and the machine frame. Dies (or molds) define the shape of the part, while punches provide the force to deform the material. High-quality alignment between dies and punches ensures accuracy and reduces material stress. Additional equipment, such as feeders and lubricators, also play a role in smooth operation. Choosing well-engineered, durable equipment is essential for consistent output and long-term productivity.

Cold heading offers several benefits compared to conventional machining:

Material Efficiency: Minimal waste is generated because the material is displaced, not cut away.

High Speed Production: Components are formed quickly, enabling large batch manufacturing.

Improved Strength: The cold deformation process enhances metal grain flow, increasing fatigue resistance.

Precision and Consistency: Tight dimensional tolerances are maintained across batches, reducing rework and scrap.

These advantages make cold heading especially attractive for manufacturers seeking both cost savings and high-quality output.

A variety of metals can be formed using cold heading, including:

Steel: Commonly used for bolts, screws, and structural fasteners.

Aluminum: Lightweight components with moderate strength requirements.

Copper and Brass: Used for electrical fasteners and decorative hardware.

The process is particularly effective for ductile metals that can withstand deformation without cracking. Selecting the appropriate material ensures both machinability and final part performance.

Cold heading is widely used in industries where fasteners are critical. Typical applications include:

Automotive: Bolts, nuts, and wheel studs.

Construction: Screws, anchors, and threaded rods.

Industrial Equipment: Specialized fasteners for machinery and appliances.

Its versatility and efficiency make cold heading an ideal choice for producing high-volume, precision-critical components.

To maximize performance and longevity of cold heading machines, manufacturers should:

Regularly Inspect and Calibrate Tools: Ensures alignment and dimensional accuracy.

Clean and Lubricate Components: Prevents material buildup and reduces friction.

Use High-Quality Raw Materials: Avoids defects caused by impurities or inconsistent material properties.

Monitor Tool Wear: Replace worn dies and punches promptly to maintain consistent output.

Implementing these practices minimizes downtime, reduces scrap, and ensures long-term reliability of the equipment.

Cold heading is a highly efficient, precise, and cost-effective method for manufacturing fasteners and metal components. By understanding the process, selecting the right equipment, leveraging its advantages, and maintaining quality through proper care, manufacturers can produce durable, consistent, and high-strength parts. For industries ranging from automotive to construction, cold heading remains a reliable choice for modern manufacturing needs. Feel free to contact WXING!