Consistency and precision are at the heart of successful manufacturing with cold heading machines. While many factors influence production outcomes, certain components play a decisive role in ensuring that each part meets stringent quality standards.

Understanding these components, their importance, and how to care for them can make a significant difference in product consistency, surface finish, and overall reliability.

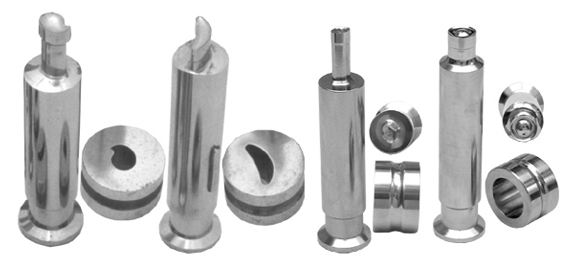

Dies, often referred to as molds, are the primary shaping elements of a cold heading machine. They define the geometry, dimensions, and surface finish of the final workpiece. A well-designed, precisely machined die ensures that each part consistently meets specifications, minimizing dimensional variation and surface imperfections.

Punches apply the forming force that guides material flow within the dies. Their precision determines how uniformly the metal deforms, directly affecting the structural integrity and strength of the finished component. Misaligned or worn punches can lead to uneven shapes, weak points, or defects that compromise part quality.

The relationship between dies and punches is crucial. Proper alignment and fit ensure that force is evenly distributed during forming, preventing defects such as cracks, burrs, or inconsistent thread profiles. Even slight misalignment can magnify errors, making careful setup and monitoring essential.

The dies and punches are at the very heart of product quality in cold heading machines. Their precision governs every aspect of the final workpiece—from accurate dimensions and smooth surface finish to consistent strength and structural integrity. Worn or poorly maintained dies and punches can lead to scrap, increased rework, and unpredictable outcomes, undermining both efficiency and reliability. By focusing attention on these components, manufacturers can ensure that each part produced not only meets but exceeds quality expectations.

Routine inspection and calibration of dies and punches help maintain dimensional accuracy. By monitoring alignment and wear, small deviations can be corrected before they affect product quality, preventing costly scrap and downtime.

Keeping dies and punches free from debris is essential. Residual material can interfere with forming, creating defects or scratches. Regular cleaning combined with proper lubrication reduces friction, minimizes heat buildup, and prolongs the lifespan of the components.

Selecting dies and punches made from high-quality tool steel or carbide is a subtle yet critical consideration. While some may overlook material quality, using inferior components accelerates wear, reduces consistency, and increases the risk of defects. Investing in durable, high-grade materials ensures that the machine operates reliably over time and maintains the high standards your production demands.

Attention to dies and punches, along with proper maintenance and high-quality materials, forms the foundation of consistent, high-quality cold heading production. Small daily practices—like calibration, cleaning, and material selection—can prevent defects, reduce waste, and extend the life of these critical components. With careful care and mindfulness, cold heading machines can deliver reliable, precision-engineered parts for years to come.