When it comes to manufacturing precision parts for industries like automotive, aerospace, and electronics, the quality and efficiency of cold heading machines play a vital role. These machines are the backbone of creating parts with intricate shapes and tight tolerances. Choosing the right cold heading machine manufacturer is crucial to ensure the reliability, productivity, and profitability of a manufacturing operation. A trusted manufacturer will not only provide high-performance machines but also offer long-term support, cost efficiency, and innovative solutions to meet evolving industrial demands.

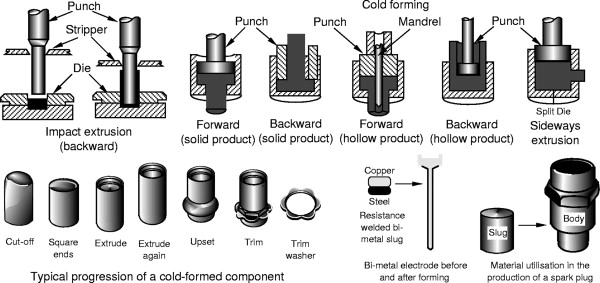

A good cold heading machine manufacturer should have deep expertise in the cold heading process and technology. Cold heading, also known as cold forging, is a highly specialized process that involves shaping metal at room temperature through a series of controlled deformations. A manufacturer with a strong grasp of this process can offer machines that produce high-quality parts efficiently while minimizing waste.

The best manufacturers continuously innovate their cold heading technology to optimize the entire process, improving part accuracy, cycle times, and machine uptime. A good cold heading machine should be capable of processing a wide range of materials, from low-carbon steel to high-strength alloys, offering flexibility in production.

Advanced manufacturing facilities are key indicators of a good cold heading machine manufacturer. The equipment used in production must be state-of-the-art, ensuring precision and reliability in every machine produced. A reputable manufacturer invests in high-quality CNC machines, automated assembly lines, and precise testing tools to guarantee that each cold heading machine meets rigorous quality standards.

By leveraging automation and sophisticated technologies, manufacturers can streamline production, enhance machine capabilities, and reduce human error, leading to machines that perform with high precision and consistency.

The foundation of a reliable cold heading machine manufacturer lies in their commitment to quality control and compliance with international standards. A good manufacturer will adhere to strict quality management systems, ensuring that every machine undergoes comprehensive testing before it leaves the factory floor.

Manufacturers who are ISO 9001 and IATF 16949 certified demonstrate a commitment to maintaining the highest standards in quality control, both in the production process and in the final product. Regular product audits and testing ensure that the machines meet customer expectations and comply with industry standards.

An excellent cold heading machine manufacturer not only provides high-quality equipment but also offers exceptional after-sales support. This includes installation services, regular maintenance, operator training, and troubleshooting. A strong customer service team can address any issues that arise during machine operation and ensure minimal downtime, which is critical for maintaining productivity.

Manufacturers with a global service network can provide timely support and on-site services, ensuring that customers, regardless of location, receive the assistance they need when they need it. Prompt response times and effective solutions are essential for maintaining smooth operations in the long run.

WXING boasts years of research and development experience in the cold heading machine sector. The company has a deep understanding of the intricate details and challenges of the cold heading process. Their commitment to continuous innovation allows them to offer customized solutions tailored to meet the specific needs of customers in industries such as automotive, aerospace, and more.

WXING employs cutting-edge manufacturing equipment and automated production lines to ensure the precision and stability of every cold heading machine they produce. Their state-of-the-art facilities ensure that each machine is built with meticulous attention to detail, incorporating advanced technologies that improve performance, reduce waste, and extend machine lifespan.

WXING adheres to the highest international standards, including ISO 9001 and IATF 16949 certifications. Regular product testing and quality inspections are integral to their manufacturing process, ensuring that every machine meets stringent reliability and performance requirements. This commitment to quality control ensures long-term stability and efficient operation for customers.

WXING’s customer service goes beyond just providing equipment. They offer comprehensive after-sales support, including technical training, maintenance services, and troubleshooting. With a global service network, WXING ensures that customers worldwide receive timely and effective assistance, keeping their production lines running smoothly and efficiently.

WXING focuses on providing machines that are not only efficient but also cost-effective. Their cold heading machines are designed to be energy-efficient and low-maintenance, helping customers reduce operational costs while maximizing productivity. By offering competitive pricing, WXING ensures that customers get the best value for their investment in high-performance cold heading machines.