Cold heading, also known as cold forming, is a metalworking process in which wire or rod is transformed into a desired shape at room temperature. Unlike hot forging, cold heading doesn’t require external heating; instead, it relies on the material’s ductility to flow under high pressure. This method is widely used for producing fasteners—such as bolts, screws, and rivets—and delivers superior dimensional accuracy, excellent surface finish, and minimal material waste. Because the metal is never heated above its recrystallization temperature, the grains within the material remain intact, resulting in increased strength and fatigue resistance.

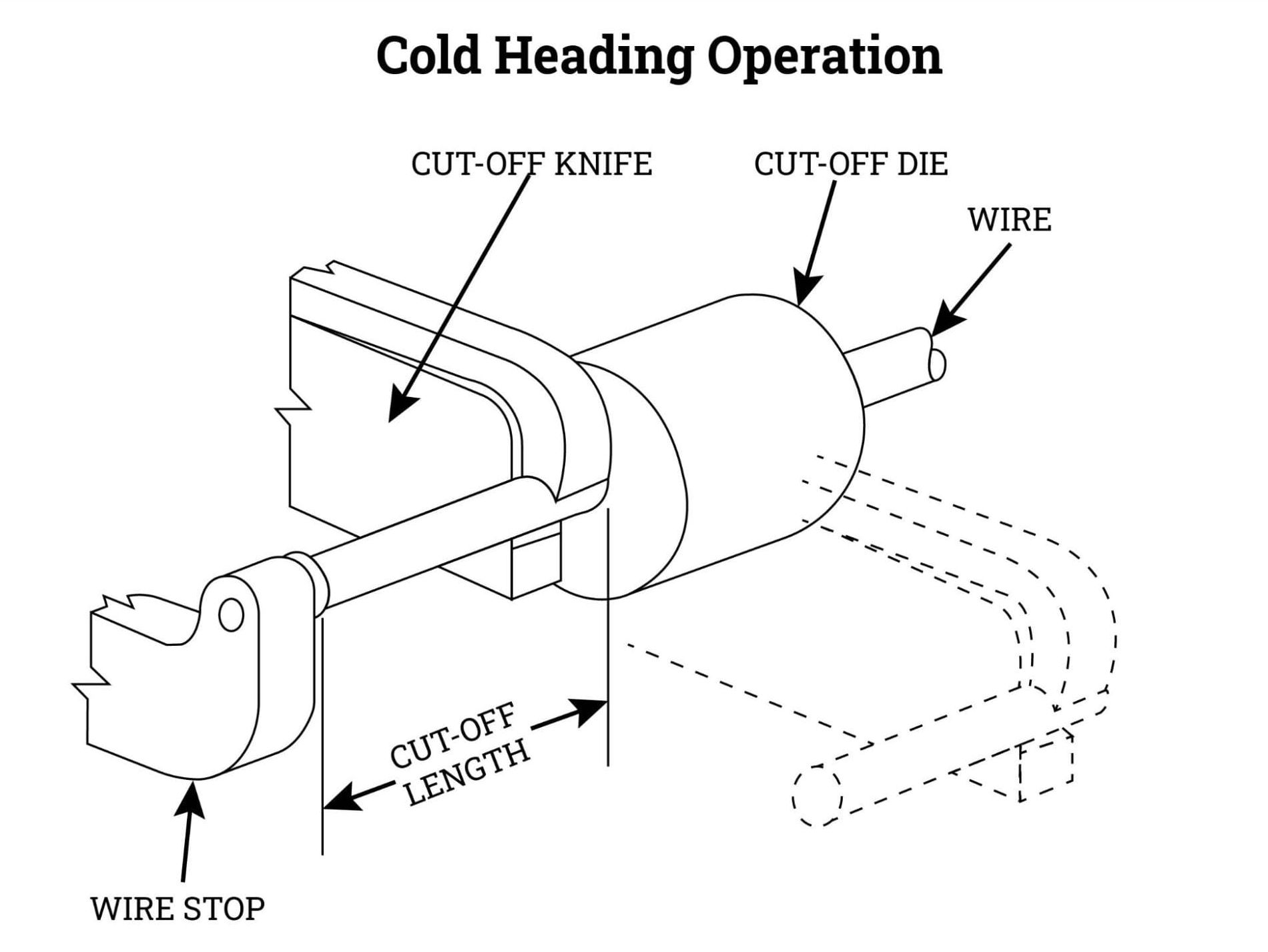

A spool of wire is mounted on a pay-off reel and guided through a straightening mechanism to remove bends or coils. The wire is then fed into the machine to the correct length (blank).

A precision shear cuts the wire to create a “blank” of uniform length. This blank is the starting point for the forming sequence.

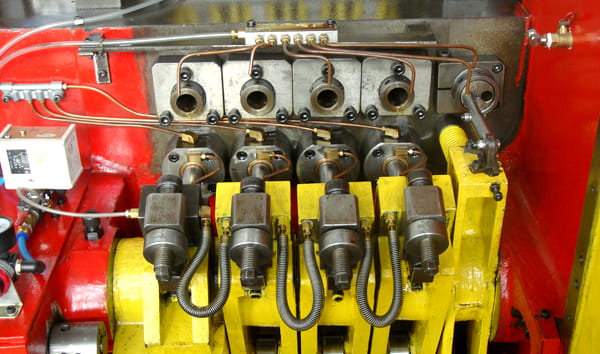

Cold heading machines typically feature multiple stations (or “drives”). Each station applies progressively higher pressure to reshape the blank:

After the final station, the newly formed part is ejected from the die. An integrated conveyor or chute then directs the finished components to packaging or secondary operations.

Automatic gauging systems may inspect critical dimensions (e.g., head diameter, shank length) in-line, ensuring parts meet tolerance and reducing scrap.

Cold heading machines are prized for high-volume, high-precision parts. Common cold-headed components include:

Their versatility also extends to custom shapes like flanges, 4-way crosses, and multi-lobed forms, depending on die design.

| Feature | Cold Heading | Hot Forging |

| Temperature | Room temperature | Above recrystallization temperature |

| Material Strength | Enhanced due to work hardening | Can be lower if not heat-treated afterward |

| Surface Finish | Excellent—minimal scale or oxidation | Often requires surface cleaning |

| Dimensional Accuracy | High tolerances achievable | Tolerances looser; secondary machining may be needed |

| Material Utilization | Up to 98% (very little scrap) | Lower, due to flash and trimming |

| Production Speed | Very high cycle rates (hundreds per minute) | Slower; dependent on heating cycles |

| Tooling Costs | Higher initial die cost; amortized over volume | Lower die cost but higher operating cost |

Cold heading excels in applications demanding high strength, precision, and volume, while hot forging remains a go-to for larger, bulkier parts where heat transfer is less of a concern.