Cold heading is a metal forming process that shapes metal parts—often bolts, screws, and rivets—without using heat. Instead of melting or machining, the process relies on applying high pressure to a metal wire at room temperature to form the desired shape. This makes cold heading a fast, efficient, and waste-free method compared with traditional machining or hot forging.

One of the key advantages of cold heading is that it enhances the strength of the metal. Since the process compresses and realigns the grain structure instead of cutting it, the resulting part maintains excellent mechanical properties, durability, and uniformity. For industries like automotive, aerospace, and construction, these benefits make cold heading indispensable for mass production of precision fasteners.

A cold heading machine is a complex system designed to perform multiple forming operations in rapid succession. The main components include:

These parts work together in precise coordination, enabling the production of thousands of identical parts per hour with minimal waste.

The process begins with feeding metal wire from a coil into the machine. The wire is usually made from low- to medium-carbon steel, stainless steel, aluminum, or other ductile metals. The feeding system ensures a consistent supply and maintains proper alignment to prevent jamming or irregular cuts. Before entering the machine, the wire may pass through a straightener to eliminate any bends, ensuring accuracy during forming.

Once the wire is in position, a mechanical or hydraulic cut-off knife slices it into a short piece known as a blank. The length of each blank is precisely controlled since it directly affects the final part’s size and shape. For high-speed machines, this cutting happens in milliseconds, with synchronization between feeding and cutting to maintain consistent production flow.

After cutting, the blank is transferred to the die station, where it will be formed. In single-station cold heading machines, the blank remains in one position for shaping. In multi-station models, transfer mechanisms—such as mechanical fingers or grippers—move the blank through several dies and punches. Each station performs a specific forming step, such as upsetting, extrusion, or piercing, progressively shaping the part.

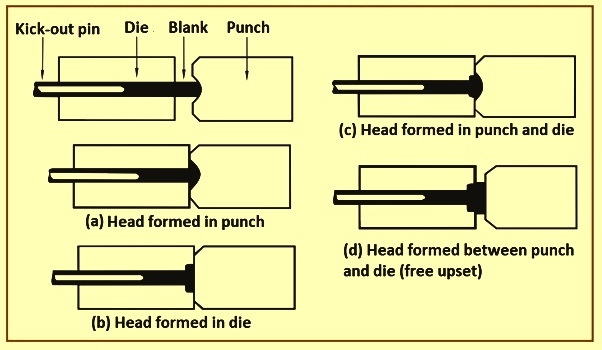

This is the heart of the cold heading process. The machine’s punches strike the blank with immense force, pressing it into the die cavity. Each blow changes the metal’s shape without removing material.

For example, the first blow might flatten one end to create a head, while the second or third blow might refine its dimensions or form more complex features like recesses or shanks. Multi-station cold heading machines can perform several blows in sequence, allowing for intricate geometries with high precision.

During this stage, the metal’s grain flow follows the shape of the part, improving its strength and resistance to fatigue—one of the main reasons cold-headed parts are stronger than machined ones.

After the forming sequence, the finished part is ejected from the die cavity. The ejection system pushes it out gently to avoid surface damage. From here, the part may be automatically collected in bins or transferred to secondary processes such as thread rolling, trimming, or heat treatment.

The machine immediately resets for the next cycle, maintaining a continuous production rhythm. High-speed cold heading machines can complete hundreds of cycles per minute, making them ideal for large-scale manufacturing where consistency and speed are essential.